Steel Manufacturer

Industry

Lindon, UT

Headquarters

Mid-Market

Company Size

Peak Demand Savings

Primary Use Case

Schaeffer Industries, a leading steel manufacturer in Lindon, Utah, has delivered high-quality, American-made steel for over two decades. Partnering with Torus, they installed a modular power plant through Rocky Mountain Power's Wattsmart Battery Program. This system delivers significant cost savings through demand charge reduction while improving power quality for energy-intensive manufacturing operations.

Schaeffer's Challenges

- High demand spikes from welding, cutting, and rolling steel operations that cannot be rescheduled or modified

- Costly utility penalties applied to unavoidable energy peaks and poor power factor

- Power quality issues affecting industrial equipment performance

- Difficulty visualizing and managing energy fluctuations across daily, weekly, and monthly cycles

Solutions & Outcomes

- Projected $25,000 annual reduction to Schaeffer's peak-demand charges

- Power factor no longer below utility limit, further reducing energy costs

- Protection against power quality issues like nuisance trips and damage to key production equipment

- Real-time data on energy usage and facility power quality

The Wattsmart Battery Program

Through Rocky Mountain Power's Wattsmart Battery Program, Schaeffer was able to install their Torus system for a low monthly subscription—no capital investment required.

Reducing Peak Demand Charges

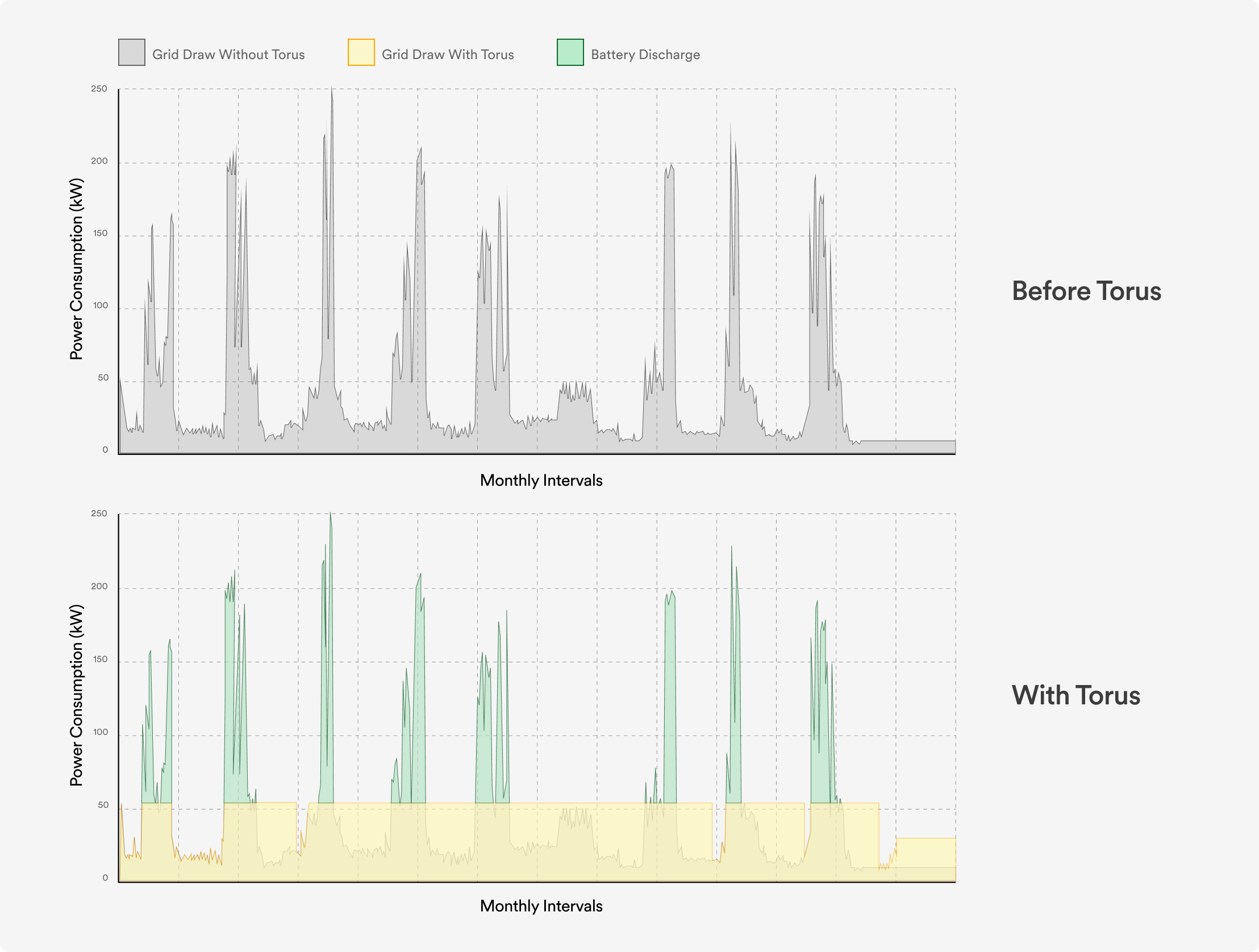

Under their utility plan, Schaeffer is charged a substantial fee for their peak power usage every month. Unsurprisingly, their top priority was addressing these unavoidable demand spikes from welding, cutting, and rolling operations.

Upon analyzing Schaeffer’s electricity load profile, two things became apparent: First, the energy peaks were huge. Second, Torus absolutely had the technology to help serve those peaks.

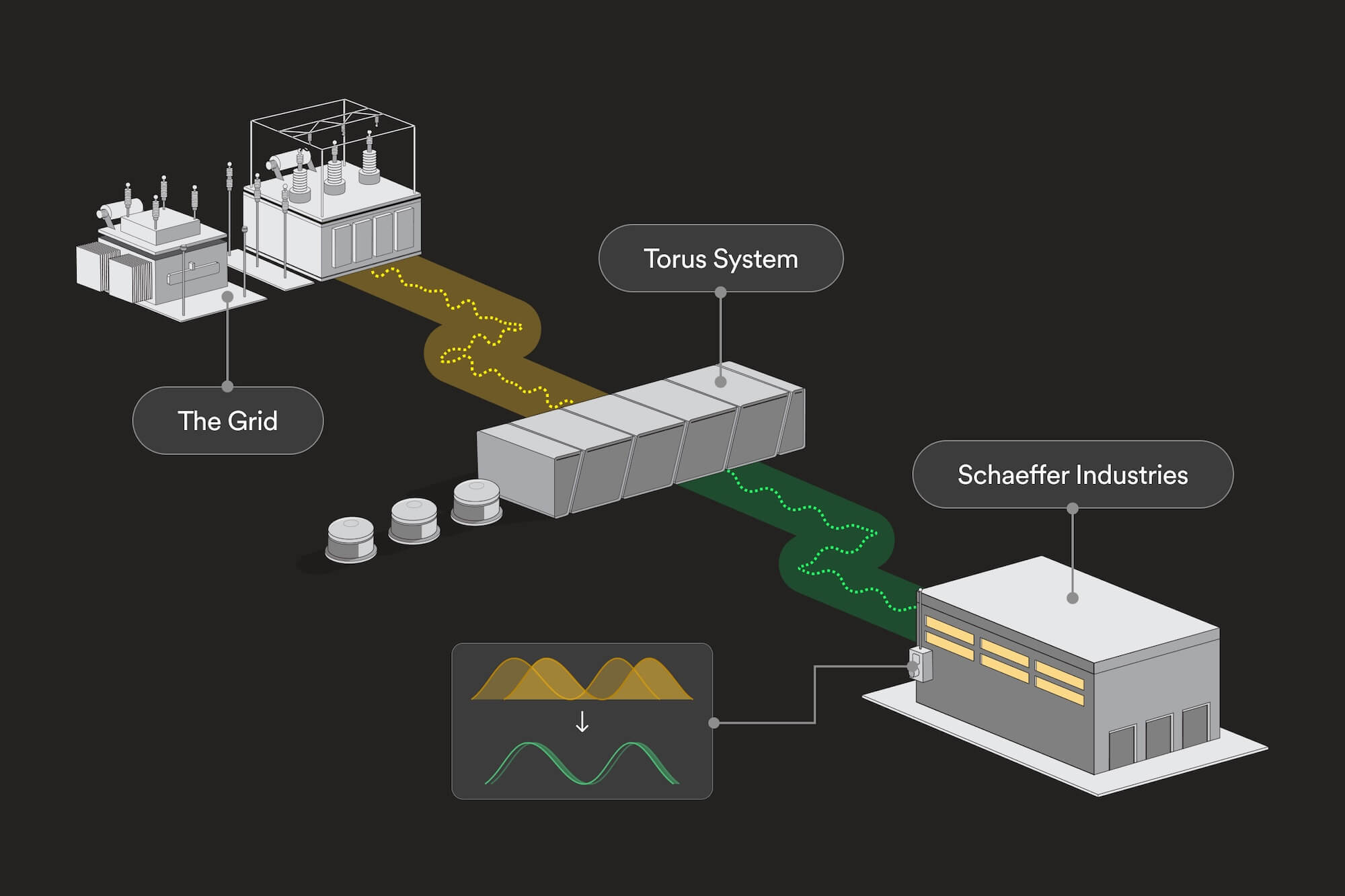

With Torus, Schaeffer no longer pulls as much power from the grid to perform these critical tasks. Instead, their system instantly discharges power when demand surges, covering those costly peaks with stored electricity. Their resulting savings are projected to total $25,000 a year in reduced demand charges alone.

Correcting Power Factor

Schaeffer's Torus system doesn't just reduce peak demand; it corrects power factor issues common in heavy industrial facilities with large motor loads. Prior to Torus, Schaeffer was operating at a power factor below their utility's limit, further increasing the penalties on their monthly bills. By providing reactive power support and managing the phase relationship between voltage and current, their system reduces wasted energy and improves overall electrical efficiency. This power factor correction translates to lower energy costs and more efficient operation of motors, transformers, and other electrical equipment throughout the facility.

Improving Power Quality

Torus Spin—the system's flywheel—delivers cleaner, more stable power by smoothing voltage fluctuations and filtering electrical disturbances that can damage sensitive equipment. Spin responds instantly to power quality events, correcting deviations, while built-in monitoring and management software continuously optimizes energy delivery, protecting Schaeffer's heavy industrial equipment from power variations that could cause downtime, equipment damage, or production quality issues.

Supporting the Grid

Through Rocky Mountain Power's Wattsmart Battery Program, Schaeffer's system functions as part of a "virtual power plant" that strengthens the regional grid. While Schaeffer enjoys the system benefits 99% of the time, the utility can use the system to balance the grid during high-demand periods. This arrangement enhances grid stability for other manufacturers in Lindon's industrial park and reduces Rocky Mountain Power's need for costly new central power plants and transmission infrastructure. The installation demonstrates how distributed energy storage creates a win-win scenario: Schaeffer eliminates costs and improves operations, and Rocky Mountain Power builds grid resilience without major capital investments.

Strengthening American Industry

Schaeffer isn't just a customer of Torus—they're also a supplier. Located just 40 miles apart in Utah, Schaeffer's steel production directly supplies Torus with the raw materials needed to manufacture energy storage systems, while Torus technology enables Schaeffer to operate more efficiently and cost-effectively. With 90% of Torus materials sourced from the U.S. and 80% procured within 150 miles of their Salt Lake City headquarters, this partnership demonstrates how domestic supply chains create mutual benefits: greater resilience, faster delivery schedules, and strengthened American manufacturing capabilities that keep critical infrastructure produced on U.S. soil.